Classifying spare parts in the after-sales service network of passenger cars based on an integrated approach of the Kraljic and the Swara technique

Keywords:

supply, car spare parts, SWARA, KraljicAbstract

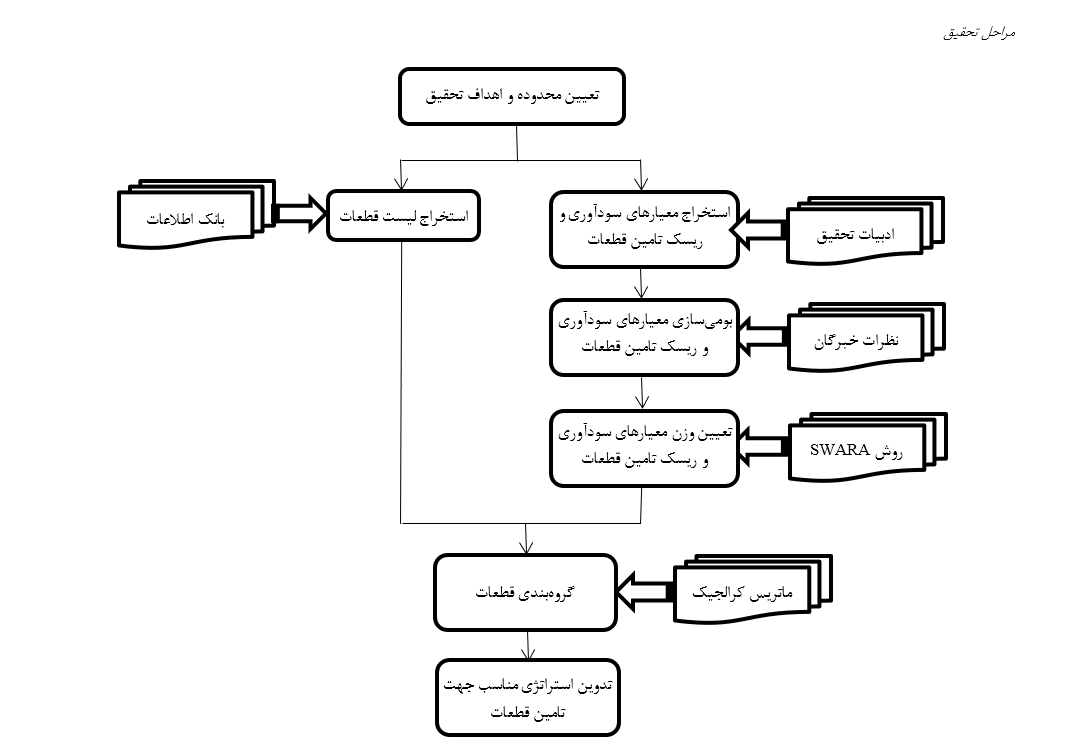

Often, the purchasing process is considered merely as a repetitive operational task and is rarely addressed strategically. For this reason, many possibilities for using purchasing as a strategic tool to achieve the long-term goals of the organization are simply ignored. This is especially important in the automotive industry and its supply chain elements, where both the diversity and consumption of their items are high. In this regard, the present study presents an approach to classifying spare parts required by the passenger car after-sales service network and developing purchasing strategies appropriate to each group. In the proposed approach, the SWARA technique is used to evaluate and weight the criteria and then the parts under consideration are categorized using the Kraljic portfolio matrix. In this assessment, current issues such as sanctions and the effect of dependence on international supply sources are also considered in the dimensions of supply risk and profitability. The population of the present study is two large organizations supplying and distributing spare parts for Peugeot vehicles based on the after-sales service network, and among them, 50 high-consumption parts are examined. Finally, while classifying parts into the four areas of the Kraljic portfolio matrix, appropriate strategies for each category are suggested. Using the results of this study, it is possible to improve efficiency and reduce costs in the spare parts supply chain, as well as increase customer satisfaction.

References

[1] P. Gaiardelli, N. Saccani and L. Songini, Performance measurement of the after-sales service network—Evidence from the automotive industry, Computers in Industry, 2007, 58, p. 698–708.

[2] Gelderman, C.J., Weele, A.J., Strategic direction through purchasing portfolio management: a case study, J. Supply Chain Manag., 2002, 38 (1), p. 30–37.

[3] Olsen, R.F. and Ellram, L.M., A portfolio approach to supplier relationships, Industrial Marketing Management, 1997, 26(2), p. 101–113.

[4] Padhi, S.S., Wagner, S.M., Aggarwal, V., Positioning of commodities using the Kraljic Portfolio Matrix, J. Purch. Supply Manag., 2012, 18 (1), p. 1–8.

[5] Dubois, A. and Pedersen, A.-C., Why relationships do not fit into purchasing portfolio models—A comparison between the portfolio and industrial network approaches, European Journal of Purchasing & Supply Management, 2012, 8 (1), p. 35–42.

[6] Caniels, M.C., Gelderman, C.J., Power and interdependence in buyer–supplier relationships: a purchasing portfolio approach, Ind. Mark. Manag., 2007, 36 (2), p. 219–229.

[7] Gelderman, C.J., Van Weele, A.J., Purchasing portfolio models: a critique and update, J. Supply Chain Manag., 2005, 41 (3), p. 19–28.

[8] Kraljic, P., Purchasing must become supply management, Harv. Bus. Rev., 1983, 61 (5), p. 109–117.

[9] Gelderman, Cees J. and Marjolein C.J. Caniels, Power and interdependence in buyer–supplier relationships: A purchasing portfolio approach, Industrial Marketing Management, 2017, 18(1).

[10] Esmaelian, M., et al., Proposing an Ordered Clustering Based on the PROMETHEE Principles to Develop Purchasing Strategy in the Supply Chain, Industrial Management Journal, 2021, 14(2), p. 285–303.

[11] S. Patrucco, Andrea, Giacomo Marzi and Daniel Trabucchi, The role of absorptive capacity and big data analytics in strategic purchasing and supply chain management decisions, Technovation, 2023, 126.

[12] Spreitzenbarth, Jan Martin, Christoph Bode and Heiner Stuckenschmidt, Artificial intelligence and machine learning in purchasing and supply management: A mixed-methods review of the state-of-the-art in literature and practice, Journal of Purchasing and Supply Management, 2024, 30(1).

[13] Hamner, B., Effects of Green Purchasing Strategies on Supplier Behaviour. In: Sarkis, J. (eds), Greening the Supply Chain, Springer, 2006.

[14] Drake, P.R. and D.M. Lee, Component prioritisation for strategic purchasing and the case study of a South Korean elevator manufacturer, Advanced Manufacturing Technology, 2008, 43, p. 883–895.

[15] Ekström, T., Hilletofth, P. and Skoglund, P., Differentiation strategies for defence supply chain design, Journal of Defense Analytics and Logistics, 2020, Vol. 4 No. 2, pp. 183–202.

[16] Rahro, M., et al., An Integrated Approach to Organizational Purchasing Strategies: A Scoping Review, Journal of Business Strategies, 2022, 19(20), p. 1–29.

[17] Arantes, Amílcar and Andreia Frias Alhais, Application of a purchasing portfolio model to define medicine purchasing strategies: An empirical study, Socio-Economic Planning Sciences, 2022, 84, 101318.

[18] Augusto, B., Andrea, B., Marco, P., Jessica, R., Supply chain redesign for lead-time reduction through Kraljic purchasing portfolio and AHP integration, Benchmarking: An International Journal, 2019, 26(4).

[19] Bildsten, Louise, Jakob Rehme and Staffan Brege, Applying the Kraljic Model to the Construction Sector: The Case of a Prefab Housing Factory, Department of Management and Engineering, Linköping University, 2010, 58183, Sweden.

[20] Bamdad Soofi, J., et al., Providing a model for sourcing in manufacturing companies by combining DEMATEL, ANP, and PROMETHEE methods, Journal of Decisions & Operations Research, 2020, 5(4), p. 312–329.

[21] Yun, H., Jung, W., A portfolio theory-based optimization model for steam coal purchasing strategy: A case study of Taiwan Power Company, Journal of Purchasing and Supply Management, 2016, 22(2), p. 131–140.

[22] Yazd Khosadi, Amin, Providing an after-sales service distribution system in relation to maintenance and repair policies, 2017, Faculty of Engineering, Yazd University.

[23] Stanujkic, D., Karabasevic, D., Zavadskas, E.K., A framework for the selection of a packaging design based on the SWARA method, Inzinerine Ekonomika – Engineering Economics, 2015, 26(2), p. 181–187.

[24] Yazdi, A.K., Wanke, P.F., Hanne, T., Abdi, F. and Sarfaraz, A.H., Supplier selection in the oil & gas industry: A comprehensive approach for Multi-Criteria Decision Analysis, Socio-Economic Planning Sciences, 2022, 79, 101142.

[25] Firouzian, A., Seyed, A., Developing a thematic model of the factors and communication and strategic components of customer satisfaction with after-sales services of Isaco Company's automobiles, Cultural Studies and Communications, 2023, 19(2), p. 25–36.

Downloads

Published

Submitted

Revised

Accepted

Issue

Section

License

Copyright (c) 2025 The Decision Science and Intelligent Systems

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.